Your provider of turn-key metal hardware solution:

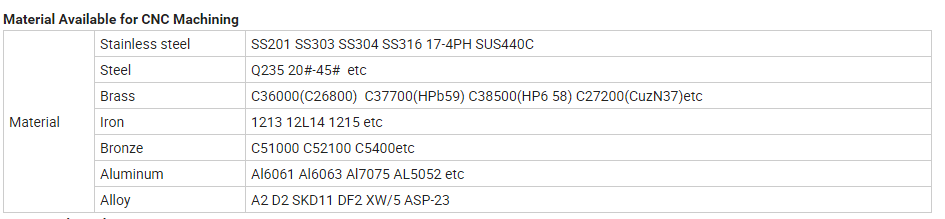

JimWell is a small-medium CNC machining workshop based in ShenZhen China, found in 2019. We are experienced in precision, prototyping and CNC machined parts fabrication, handle in types of aluminum alloys, copper alloys, and stainless steel.

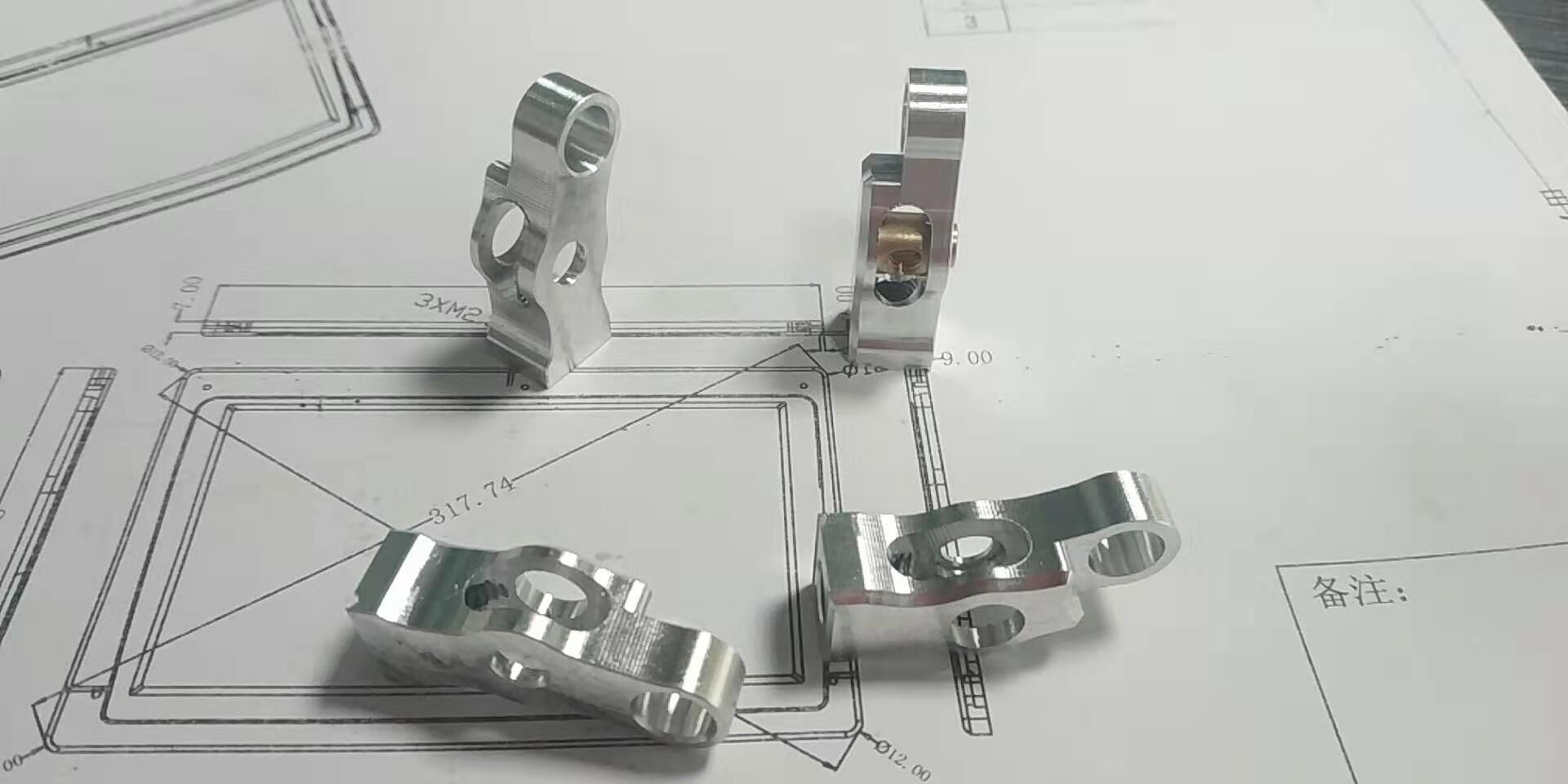

JimWell precision was created by young Mr. Jim, supplying bespoke metal edge-cutting technologies, custom precision mechanical components in many applications for sports equipment(3-wheel trucks, offroad racing bikes, motorcycles, eskateboards, and foldable ebikes..); consumer elctronics(hi-end audio equipments, tunable devices, espresso machines, underwater strobes...); quantum technologies, photonline and optoelectronics(fiber-optical, vision machines, handrail systems, lighting solutions...) ect.; as we are growing up, now we have skillful technical and great team backup to meet customers of design, engineering, and manufacturing.

Jim is passion for manufacturing high quality precision parts, he is an experienced engineer for materials and precision technology. before he started his business, he worked as a precision machine operator, and learned a lot from his job after than he studied cnc technology and advanced cnc technology, then as a cnc programmer. He know all the manufacturing procedures, management well of the workshop.

High-quality tailor-made CNC machined parts supplier:

Parts are machined using CNC-controlled machining centers and full sets of inspection equipment, it means we deliver accuracy and precision metal components for customers around the world. As developing company we consistently buy machines and inspections to meet and welcome various customers. There are more than 12 machines in Workshop: CNC machining center (3 axis, 4 axis), CNC turning, Manual milling, CNC milling, Automatic turning, Laser cutting, and Drilling machine came in our house. We have a full set of inspections by CMM, Quadratic Element, Calipers, Altimeter; we trained our staff daily using equipments in proper way and update for sure parts tested in precisely.

FROM THE CLIENT‘S IDEA TO SERIAL PRODUCTION

Jimwell deliver the complete products, it could be from prototype to mass production. We respect our customers' idea and effort to meet their demand.

There are various raw materials we work with:

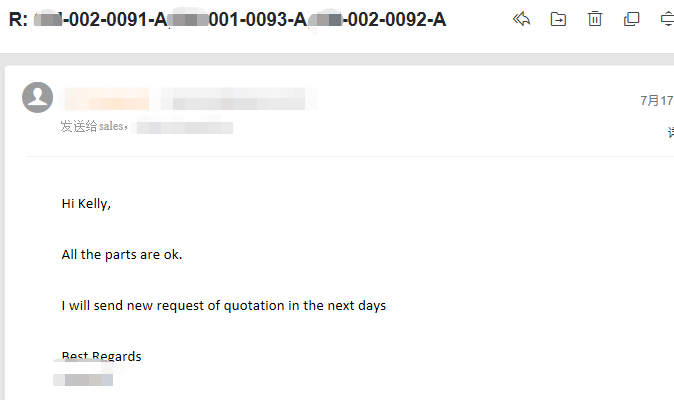

Our customers are happy for our metal spare parts:

We Care About the details:

> Materials we use is environmental and ROHS standard

> Tolerance respect technical files provided by our customers

> All of our parts are deburr and remove sharp edges

> Timing adjust advanced CMM inspector for sure part is exactly right

>Keep positive communication with our customers during unexpected things happened and find a solution to work out

>Fast and timing delivery and high quality precision machined parts

>Packing we use blister plastic bag, bubble wrap or pearl wool inside carton box, keep safe and no damage on transition

OUR MISSION: provide high quality customized machined parts at your best value, balanced with social and environmental responsibility.